Longteng Special Steel Group is a well-known private enterprise in

China's special steel industry. Founded in 1993, it is a deep

processing enterprise of metal products integrating sintering,

ironmaking, steelmaking, refining, continuous casting, rolling and

metal product processing. It has an annual output of 4.5 million

tons of various special steels and its products are sold to more

than 40 countries and regions. Longteng Special Steel Group has ten

major business segments. Its leading products include: hot-rolled

Marine sections, prestressed concrete (PC) steel bars, high-end

wear-resistant steel balls, high-end welding materials, oil and gas

pipe fittings, new energy forgings, medium and heavy plates, etc.

Among them, the three major products of Marine steel sections, PC

steel bars and wear-resistant steel balls have all become the

largest production bases in China, with market shares of over 60%

in the domestic niche industries. Among them, wear-resistant steel

balls have become the second largest supplier in the world's

grinding industry

Vice President Company of CANSI

(China Association of National Shipbuilding Industry)

Six main products series ( 5.0 million tons)

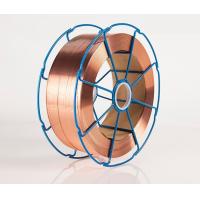

1. Welding Materials

2. Shipbuilding section

3. High-strength pre-stressed concrete steel bar

4. Forging ingot series

5. Steel ball series for bearing & mining industry

6. Flange & End Plate

7: Steel thick plate

As part of our development strategy, we have always been focused on

the complete production process model. We believe this will bring

us synergy effects. Therefore, recently, a new product, namely

welding consumables, has been added to our catalogue. It will cover

all series such as gas shielded solid welding wires, flux-cored

welding wires, submerged arc wires, argon arc wires, etc., as well

as medium and heavy plate series (thickness 6-800mm). Width:

1500mm-3650mm, maximum single weight: 60t

Our LT welding wire has two main advantages:

A fully integrated production process, that is, supported by the

world-class upstream steel manufacturing facilities of the same

group company.

The newly developed production process, which adopts the latest

technologies and know-how, namely fully automatic production, will

ensure quality control.

Our advantages of medium and heavy plates:

Complete electric furnaces and off-furnace refining equipment

The rated capacity of the ultra-high power electric furnace is 115

tons, and the maximum steel output per furnace is 130 tons

It has two 115-ton LF refining furnaces and one double-station VD

furnace

The largest-sized steel ingots and continuous casting billets

The largest flat steel ingot is 60 tons, and the largest plum

blossom steel ingot is 270 tons

The maximum single weight of the ingot steel plate: 60 tons (forged

and rolled combined process)

Continuous casting adopts the techniques of dynamic light pressing,

dynamic secondary cooling and heavy pressing

The maximum cross-sectional specification of the continuous casting

billet is 460*2600*3600mm

Complete rolling line equipment

Advanced split vertical rolling mill